Hydrostatic Test Service

CIS team provides hydrostatic testing services to test the integrity of your pressure equipment. Before being placed into service any pressurized equipment is required to be pressure tested. Examples of equipment requiring hydrotesting testing services are:

- Process Piping

- Pipelines

- Boilers

- Pressure Vessels

- Storage Tanks

Each type of equipment is subject to specific codes and inspections before it is placed into service. CIS will work with you to ensure the hydrostatic pipe testing process is executed safely and to the correct standards. Complete and accurate documentation will be produced and handed over to the required parties.

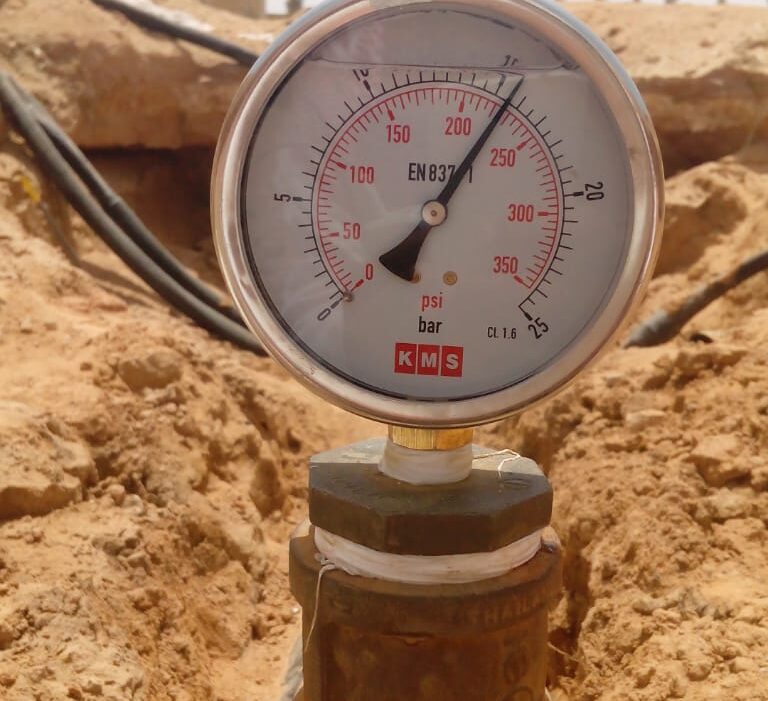

Our expert team of can respond rapidly to your request to provide equipment and perform hydrostatic testing. Safety and quality are at the forefront during hydrotesting activities. All hydrostatic tests performed by our team include a hydrotest tree with a certified gauge and relief valve to prevent over pressurization of the equipment.